Chimney ReLining Installation Services

Why is it Important to Install a Chimney Liner?

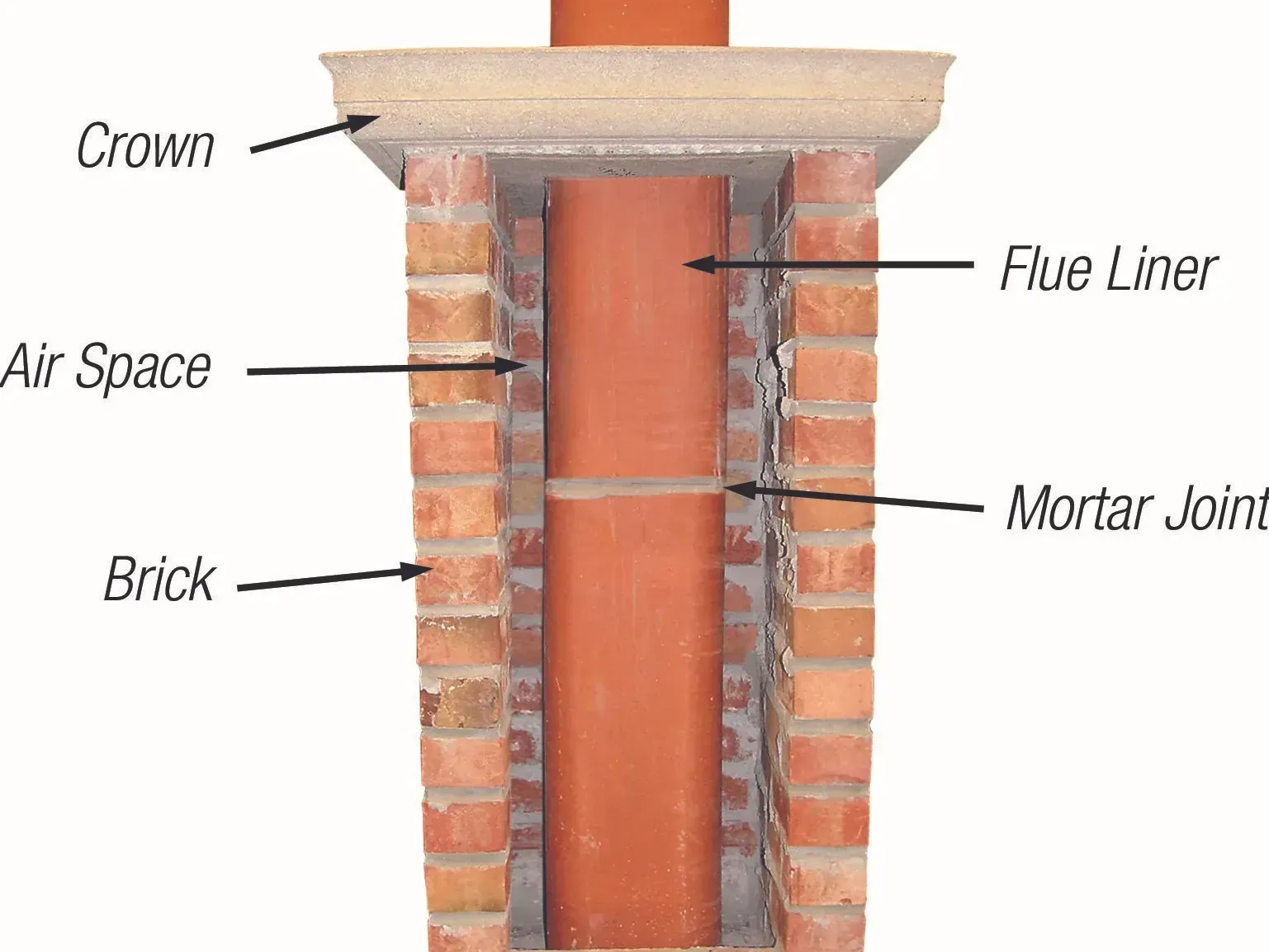

Chimney liners serve as an extra layer between the inside of the chimney and the framing of your home. This provides another layer of protection as common defects can appear in the chimney. Defects, no matter how small, can begin a process that will further erode the chimney and can pose a threat to your family’s safety through the creation of health risks. Poisonous gases could potentially infiltrate the home.

More importantly, combustible creosote or soot can also escape through these openings and build up outside the chimney flue liner. If the creosote were to catch fire in this area of your chimney, serious damage can occur because the fire can no longer be contained within the flue. Homes built prior to the 1940’s were typically built without a chimney liner. As a result, chimney and house fires were more common. To determine whether or not you need a new liner a Level II inspection would determine if you are missing a liner, if your current one was installed incorrectly and if your current liner is deteriorating. Please call ProTech Chimney Restoration at 612-567-0068 for a chimney inspection today.

Chimney Relining Options

There are several options when it comes to restoring your chimney flue liner, which is determined by inspecting the level of disrepair, and ranges from filling in the gaps in the mortar, resurfacing with a ceramic flue sealant or completely relining with a stainless steel liner.

Stainless Steel Liner

A stainless steel liner is sized to fit inside your flue and provides durable protection for all fuel types. They are corrosion and rust-resistant and built to last, with a lifetime warranty. Of all the options for repairing or relining a flue, the stainless steel liner comes with the highest price tag.

HeatShield® Chimney Relining

We are proud to be factory-trained HeatShield® Installers.

Here’s a look at the HeatShield® Lining services we offer. The service you choose will be determined by the defects found in your current chimney system. Our chimney crew will provide a video inspection to help diagnose the extent of erosion & deterioration in your clay liner.

Joint Repair

If your chimney only requires repair for defective or deteriorating mortar joints, then the Joint Repair service is the best option. With the patent pending Joint Repair system from HeatShield® your chimney is fixed right the first time. After creating a custom foam applicator blade for your chimney, our chimney sweeps will plunge the applicator tool and blade down into your chimney and position them just below the mortar joints to be fixed.

We then deploy the HeatShield® Cerfractory® Flue Sealant mixture and fill in each void in the deteriorating mortar joint with the applicator tool. As the blade is pulled up to the next location, the repaired mortar joint is smoothed out. After all of the joints have been filled, our professional chimney techs will ensure that your chimney is properly sealed.

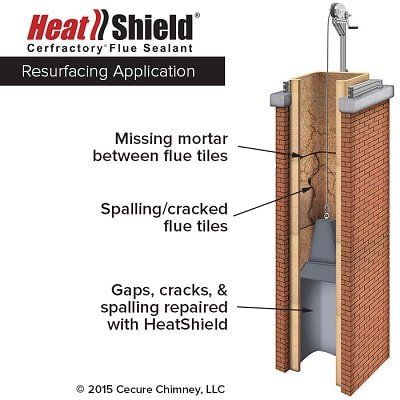

Resurfacing System

The HeatShield® Resurfacing System is a more in-depth liner repair which is used to fix chimney liners that show a great deal of deterioration. If your chimney’s clay liner contains cracks or spalled tiles but is otherwise in sound condition, the Resurfacing System is utilized to restore it back to its original condition. During this service, a special HeatShield® coating is applied over the inside of the entire flue to create a seamless corridor.

Our certified HeatShield® Installers create a specially-designed foam plug that is placed at the bottom of your flue and attached to a winch at the top of your chimney. Special chimney brushes are used to remove any debris or creosote buildup that has formed on your chimney. Once the flue is clean, an adhesive known as “tie coat” is applied to the flue walls as the plug is pulled upwards by the winch. After this adhesive has had time to set, the HeatShield® sealant is then applied in the same manner, coating the entire chimney flue and covering any cracks or areas of vulnerability that can compromise safety and performance.

PAYMENT OPTIONS

OFFICE HOURS

- Mon - Fri

- -

- Sat - Sun

- Appointment Only